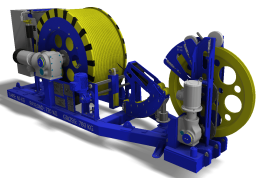

HH-253: Umbilical Management System

- Drum capacity: 450m-540m of 20mm umbilical on 8 layers

- Operational for sea state 4-5.

- Removable drum

- Complete with deck fastenings.

- Drum mounted on 1x Orkot marine bearings for maintenance free mounting.

- All other roller bearings are marine grade plastic maintenance free bearings.

- Complete with deck fastenings.

- 2 x winch operating station and service laptop mounted on bolt able back plates

- All sensors supplied and wired into control system to include umbilical temp sensor, Drum temp sensor, encoder to allow feedback for cable length pay in pay out, load pin in sheave wheel to give tension on umbilical feedback

- All enclosures including oil filled junction boxes to be fitted with water sensors

- Base frame designed from aluminium for weight saving.

- Base frame has a 60 kg tare weight able to transport 720 kg payload. Overall system weight 780 kg.

- Comes with separate lifting spreader beam and dedicated sling sets.

- Lifting can be DNV approved if required.

- Comes with driven sheave wheel to ensure tight spooling onto drum and aid in paying out umbilical.

- Winch drum and sheave wheel driven by electric motors. Motor and gearboxes are stainless steel for the marine environment.

- Independently driven level wind for remote override.

- Subsea coating on all aluminium, other items are marine grade stainless and low water absorption plastic.

- Maintenance free swivel block to aid umbilical fleeting into sheave wheel.

- Water cooling system for umbilical surface and motors if required.

- Electrical cabinets rated to IP68, or can be mounted internally on back plates and transparent covers.

- Removable front sheave wheel assembly if access to surrounding areas is required.